LX200 Autoguiding

This text describes a PIC microcontroller based LX200 protocol compatible step motor driving system for a German equatorial mount (both RA and DEC axis). The system does not implement position encoders or other kinds of positional feedback. Instead, the operation is based on the ±50% RA guiding speed change to provide tracking correction, and an angular speed equivalent in the DEC axis. The amount of applied correction is determined by the time that a particular speed change command is held active (standard method supported by most autoguiding software). The implementation presented here was configured for the GM3-RA mount that comes with a TAL 200K telescope as described here. Of course, this system can be reconfigured easily for other mounts utilizing 4-phase step motors, or it can be used as an LX200 protocol decoder only.

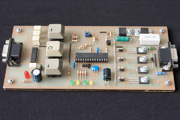

This system had the misfortune of being developed in parallel with some other work on the telescope mount, which initially didn't have a motorized DEC axis. So this first part of the controller was designed with only RA axis driving capability, and separate DEC drive was supposed to be plugged in the LX200 signal output connector. On the board you can find:

This system had the misfortune of being developed in parallel with some other work on the telescope mount, which initially didn't have a motorized DEC axis. So this first part of the controller was designed with only RA axis driving capability, and separate DEC drive was supposed to be plugged in the LX200 signal output connector. On the board you can find:

- PIC 16F73 microcontroller (LX200 decoding and RA axis step-motor driving)

- RA motor driving circuit (Four BD677 darlington transistors)

- RS232 interface

- LX200 output signal connector (RA+, RA-, DEC+, DEC-)

- Buttons for manual RA slew control

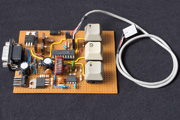

DEC controller has been built after the appropriate step motor has been selected for the mount. This board connects to the RA controller with a small cable to receive guiding signals (DEC+ and DEC-). The board itself contains:

DEC controller has been built after the appropriate step motor has been selected for the mount. This board connects to the RA controller with a small cable to receive guiding signals (DEC+ and DEC-). The board itself contains:- PIC 16F628 microcontroller (motor driving signals)

- Motor driving circuit (Four BD677 darlington transistors)

- 12V to 24V switch-mode boost converter (because the motor is rated 24V)

- Buttons for manual DEC slew control

Device Operation

Besides the addition of the LX200 interface, the RA controller alone behaves pretty much the same as the original TAL 200K controller (hand command), but with following improvements:- When holding the "Q" button together with one of the slew buttons, faster rate of movement is achieved (centering rate that is 10X the sideral tracking speed). Otherwise, slew buttons provide a ±50% tracking speed change.

- RA step motor is driven in half-step mode, achieving double the precision of the original that operates in full step mode and is much noisier as well.

- There is no delay between pressing a button and command action.

The RA controller is pin-to-pin compatible with the original hand command connector, and receives power through it as well. Since the DEC motor installed on the mount is quite larger and draws more current, DEC board was provided with a separate power connector. Buttons on the DEC controller operate in the same way as on the RA board.

LX200 Compatibility Specification

A minimal set of LX200 protocol commands has been implemented - only those that concern autoguiding and slewing. In addition to this, commands for returning the (null) values of RA and DEC position have been added also, as some autoguiding software relies on these to verify the communication with the device (e.g. Iris). This is the list of implemented commands:| Command Code: | Command Name: | Return Value: | Comment: |

| :RG# | Set Guiding Rate | - none - | 50% of the nominal RA tracking speed |

| :RC# | Set Centering Rate | - none - | 10X the nominal RA tracking speed |

| :Me# | Move East | - none - | Decrease RA tracking speed by specified rate |

| :Mw# | Move West | - none - | Increase RA tracking speed by specified rate |

| :Mn# | Move North | - none - | Move DEC north by specified rate |

| :Ms# | Move South | - none - | Move DEC south by specified rate |

| :Qe# | Quit Moving East | - none - | Cancel previously issued :Me# command |

| :Qw# | Quit Moving West | - none - | Cancel previously issued :Mw# command |

| :Qn# | Quit Moving North | - none - | Cancel previously issued :Mn# command |

| :Qs# | Quit Moving South | - none - | Cancel previously issued :Ms# command |

| :Q# | Quit All Movement | - none - | Resume tracking by nominal RA speed |

| :GR# | Get Current RA Position | 00:00:00# | Some software require this as a communication check |

| :GD# | Get Current DEC position | s00:00:00# | Some software require this as a communication check |

Note: setting the guide and centering rate makes sense only if you are using the same microcontroller to decode LX200 and drive the step motor. In this implementation, it works only on RA axis.

Microcontroller uses RS232 asynchronous serial connection (9600 baud, 8N1) to communicate. If your computer doesn't have a COM serial port connector (DB9), you can use the USB to RS232 converter cable. If you need to troubleshoot the connection, use some terminal emulation program to open the configured COM port where you connected the autoguider. You can then manually type the last two commands from the table to see if there is a response.

Downloads

Disclaimer and Copyright Notice: All of this material is provided exclusively for non-commercial use. You may copy and redistribute it freely for such use if original author's credit is preserved. The material is provided "as is", without any kind of warranty (although I hope that somebody finds it useful).LX200 Autoguiding for TAL200K

This archive contains schematics, source code and some PCB layouts for this project. I have added files regarding the SLR trigger also.